Description

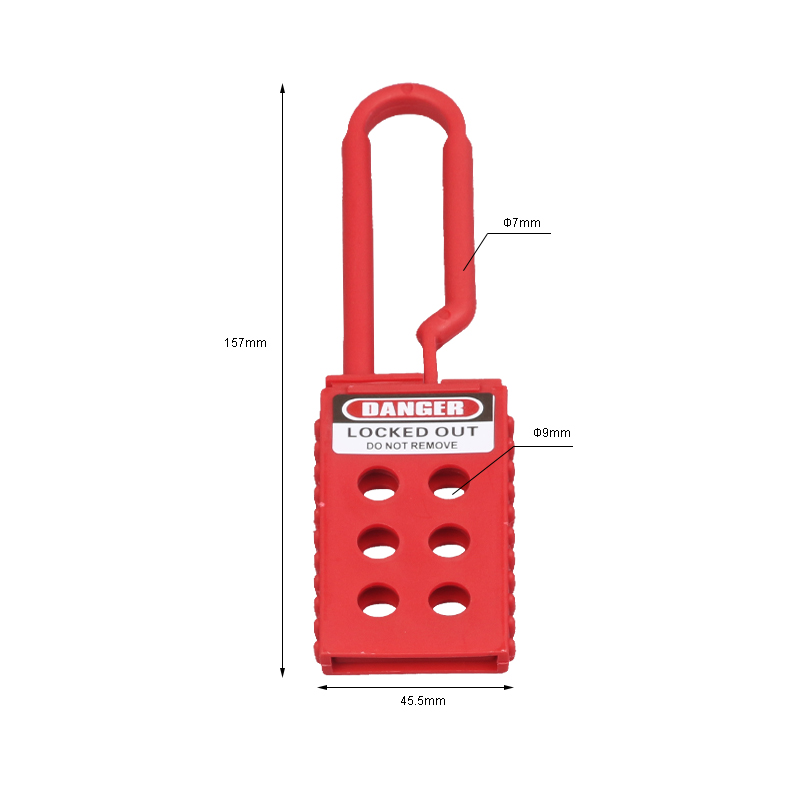

Non Conductive Lockout Hasp is manufactured from industrial grade nylon material which can accommodate up to six lockout padlocks. It acts as a Group Lockout device which allows multiple workers to apply their padlocks at the lockout point. The safety hasp keeps equipment isolated during maintenance and repairs. The energy point cannot be turned ON until last worker’s padlock is removed from hasp. The product dimensions are Dimensions are 41mm x 174mm with 25mm x 64mm inside jaw diameter.

The Lockout Hasps are important to any lockout program or procedure as they help provide effective group lockout system. Multiple employees can apply their padlocks to the Lockout Hasps which allows an energy point to be isolated by more than one employee. It ensures the energy source is completely isolated and can’t be operated until each employee removes their lockout padlock from the hasp.

The Non Conductive Lockout Hasp is OSHA compliant and is available for delivery across Danmark, Norge, Sverige, Suomi and entire European region from our distribution center in Zagreb, Croatia.

Lockout Tagout (LOTO) practices and procedures safeguard employees from hazardous energy releases. OSHA’s Lockout/Tagout fact sheet describes the practices and procedures necessary to disable machinery or equipment to prevent hazardous energy release. The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout) (29 CFR 1910.147) for general industry outlines measures for controlling different types of hazardous energy. Employee training is required for each worker to ensure that they know, understand, and are able to follow the applicable provisions of the hazardous energy control procedures.

Reviews

There are no reviews yet.